The global demand for renewable energy is rapidly growing at a record pace, & solar energy is certainly leading this particular transformation. From the millions of residential rooftops to the massive utility-scale plants, the high-performing solar panels are now undeniably constituting a core part of the world’s clean energy infrastructure. But have you ever wondered what goes behind the making of an optimally high-efficiency solar module?

It all starts inside a solar panel production line, where certain hi-tech & advanced engineering, precision machinery, & automation are very well compiled together to shape the future of energy.

What Is Meant by a Solar Panel Production Line?

A solar panel production line is not merely a space where panels are being assembled - it is a fully optimized ecosystem of the most specialized equipment, robotics, & various testing technologies. The line usually carries a solar cell from raw wafer processing all the way to a finished solar module that is fully ready for the purpose of installation in various real-world conditions.

This likely includes various processes like lamination, framing, junction box fixing, EL testing, & inspection of final quality, all under a single seamless, & automated setup.

Why Automation Matters the Most in Solar Manufacturing?

Automation undeniably plays a highly significant role in ensuring the overall reliability & long life of the various solar modules. Every single panel must have the capacity to withstand high temperatures, harsh weather condition, & several years of field exposure. The more automated the line, the less margin there is for human error - & the better the performance of the final product.

A modern and contemporary solar panel production line includes the following:

· High-precision cutting & cell stringing machines

· Completely automated tabber & stringer systems

· Advanced lamination units for the purpose of high durability

· Inline performance testing in order to ensure high level of efficiency

Automation also helps manufacturers scale quickly, reduce waste, & maintain consistent quality. All of these are highly essential to stay highly competitive globally.

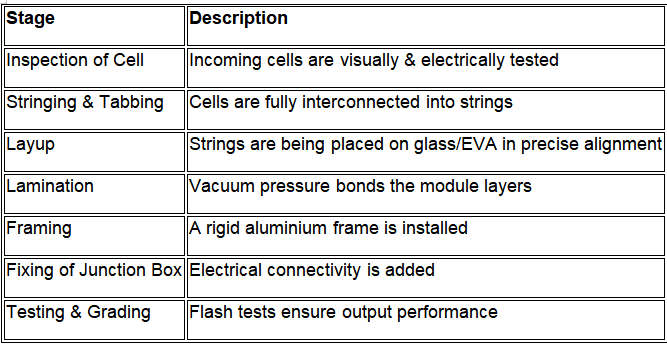

Major Stages in the Process of Solar Module Manufacturing

Here is a simplified breakdown of what typically happens inside a fully equipped production unit:

Each of these steps relies on highly specialized machines, optimized for the desired speed, accuracy, & minimal material loss.

Why Should You Choose Cliantech Solutions?

For manufacturers who are planning to scale or set up new solar facilities, choosing the right technology partner is very critical. Cliantech Solutions provides world-class PV module line equipment with the best automation capabilities that are well-suited for all - small, medium, & utility-scale production units.

They not just supply equipment but also assist with the following:

· Layout design

· Installation of Machine

· Process Optimization of the process

· Production training

· After-sales support

This specifically makes Cliantech a complete ecosystem partner rather than just a supplier of equipment.

Conclusion

As global solar adoption continues to accelerate, efficient manufacturing is indeed becoming the heart of industry growth. A well-designed solar panel production line always ensures quality, consistency, & high level of cost-effectiveness - all of which are highly crucial for the sustainability of long-term business in this sector.

No matter if you are planning to establish a new PV module facility or upgrade your existing plant, the most advanced automation technology will certainly be the key to gaining a high competitive edge. With partners like Cliantech Solutions, manufacturers can very well stay prepared & future-ready to align with the global clean energy transition.

Write a comment ...